Multiwire brassing lines

Single wire and multiwire lines for electrolytic plating of steel and copper wire

Multiwire brassing lines

For Steelcord-For Saw wire-For Hose wire

Complete lines for wire brassing. The technological positions may have specificities in function of the required technical data of the final product; yet, in general terms these positions are the following ones:

- Multiwire brassing lines

- Complete lines for wire brassing

- initial cleaning section upstream the heat treatment furnace

- heat treatment

- wire cooling after heat treatment

- electrolytic pickling

- activation

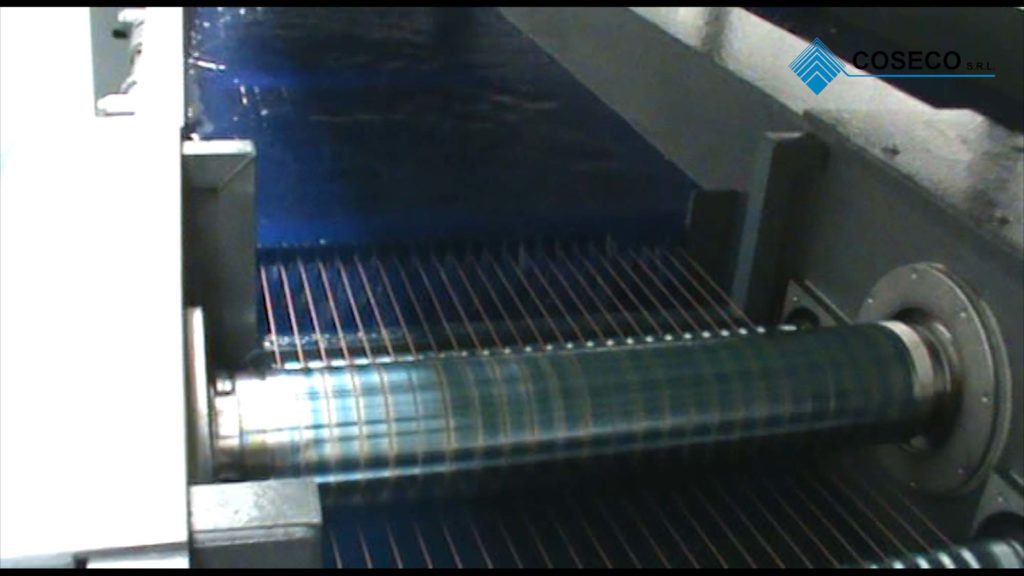

- electrolytic alkaline coppering

- electrolytic acid coppering

- electrolytic zincking

- diffusion

- final surface conditioning of the brassed wire

Coppering vessel with insoluble anodes for regulating the content of copper in the solution