Using its know how in treating the surface of wire, Coseco developed plants for in-line pickling and passivating the surface of welded pipes in stainless steel. These plants are integrated in the tube manufacturing lines, namely downstream the profiling and welding bench (and the annealing furnace –if installed), and upstream the flying shear. So complete a line allows for manufacturing welded pipes in stainless steel starting from the strip and ending with the final product, cut to length. The Coseco plant may be composed of the sole section for electrolytic pickling and passivating, or be equipped with the additional station for ultrasonic cleaning – depending on Customer’s industrial requirements.

It consists in the following technological parts:

- Inlet group with adjustable height,

- allowing for regulating the level of the tube axis in function of the pipe diameter;

- Electrolytic pickling and passivating

- Two stage rinsing

- Ultrasonic cleaning (when required)

- Final drying with hot air

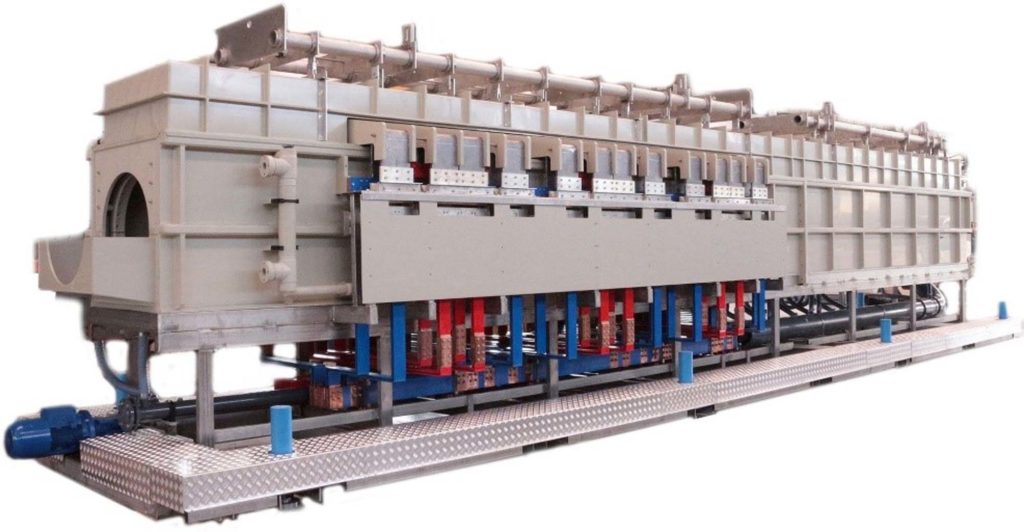

The unit is supplied “turn-key”, installed on a foundation plate, with aboard all the necessary devices, such as pumps, heat exchangers, electrodes, acid tank, electrical cabinet with control system. The unit comes ready to be connected to the Customer’s power net, to his water and compressed air supply, as well as to his central acid tank for making-up of the unit’s tank .

The plants are engineered upon Customer’s technical requirements. So far were supplied plants covering the following tube diameter range:

- from 08 mm to 35 mm

- from 23 mm to 76 mm

- from 57 mm to 76 mm

- from 73 mm to 114 mm

- from 202 mm to 406 mm

- from 273 mm to 609 mm