High speed coppering lines with coppering vessel showing multigroove capstans with horizontal axes (for wire with small diameter, as, for example, MIG welding wire)

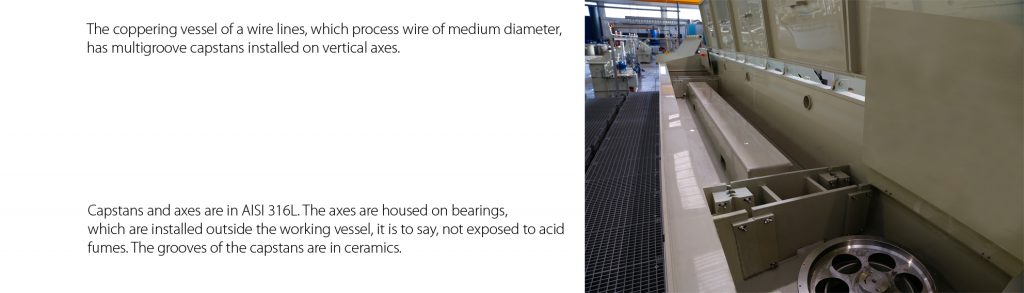

High speed coppering lines with coppering vessel showing multigroove capstans with vertical capstans (for wire with medium diameter)

Straight coppering lines (for big diameter wire) for example, for Subarc welding wire, for an industrial semi-processed good

High speed coppering lines with coppering vessel showing multigroove capstans with vertical capstans

The chemical coppering lines include the following technological positions:

- Wire cleaning at line entry

- Acid coppering

- Rinsing

- Neutralizing

- Drying

Coseco offers different solutions for cleaning the wire: degreasing in hot water / degreasing in a diluted acid / degreasing in hot water and electrolytic pickling.

The choice of the most appropriated solution for each single case depends on a number of parameters: state of the surface of the incoming wire, habitudes of the Customer, etc. After the coppering the wire is rinsed in a multistage vessel. The multistage rinsing allows for a high reduction of the water consumption. Depending on Customer’s requirements, the lines may be supplied with all the ancillary tanks required to prepare the working solutions, or ready for connecting them to his utilities. The lines are equipped with all the required security devices to protect the operator and the environment. The fume collecting system is an integrated part of a standard line.